Working Hours | 9:30am - 6pm

- Home Page

- About Us

-

Our Products

- Chlorine Free Disinfectant

- Chrome Purifier Unit

- SOLUTION WITH CAPTURED IMPURITIES

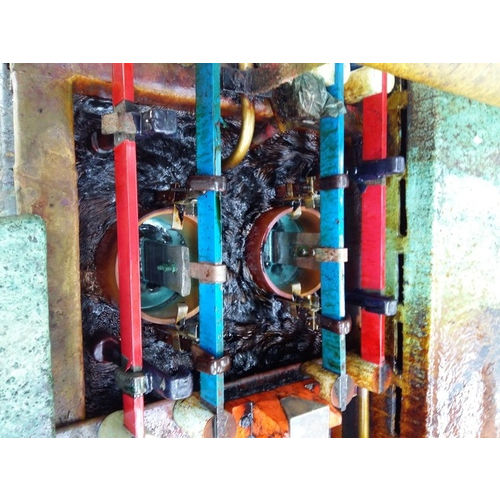

- TRIPLE DIAPHRAGM CHROME PURIFIER IN OPERATION

- TRIPLE DIAPHRAGM CHROME PURIFIER UNIT

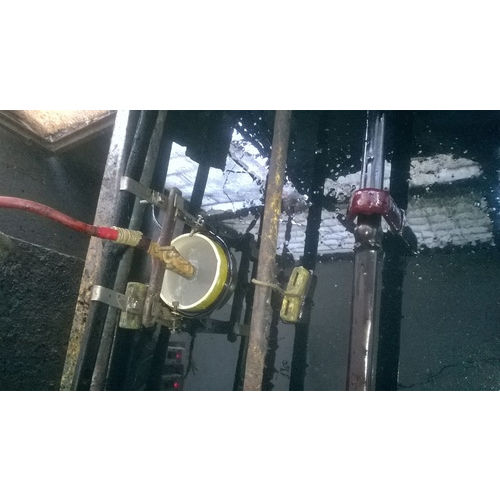

- CHROME PURIFIER UNIT IN OPERATION

- Chrome Purifier Diaphragm (3.3 LTRS)

- CAPTURED IMPURITIES SETTLED AT THE BOTTOM

- Fresh Diaphragm Solution

- Chrome Purifier Diaphragm (12.5 LTRS)

- Cuboidal Diaphragm

- CHROME PURIFIER UNIT INSTALLED

- CHROME PURIFYING UNIT

- CHROME PURIFIER IN OPERATION

- Chrome Purifier

- Chrome Purifying Unit

- Specific Diaphragms

- Single Diaphragm uni

- Industrial Chrome Purifier Unit

- Multi Diaphragm unit

- Chrome Purifier System

- CR PURIFIER UNIT

- Single Unit Chrome Purifiers

- SINGLE DIAPHR CHROME PURFR UNIT 3.3 LTR (2)

- Single Diaphr Chrome Purfr 12.5 Ltr In Operation

- Chrome Purfr Unit - Settled Metallic Impurities

- SINGLE DIAPHR CHROME PURIFIER UNIT 3.3 LTR

- CHROME PUIRIFIER. DIAPHR 12.5 And 3.3 LTR

- SINGLE DIAPHR CHROME PURIFIER UNIT 12.5 And 3.3 LTR

- Single Diaphr Cr Purfr Unit 12.5 Ltr In Operation

- Single Unit Diaphragm Chrome Purifiers

- Single Unit Chrome Purifier In Operation

- SINGLE DIAPHR CHROME PURFR UNIT 3.3 LTR (3)

- SINGLE DIAPHR CHROME PURIFIER UNIT 12.5 LTR

- DIAPHRAGM (12.5 LTRS)

- DIAPHRAGM 3.3 Ltr

- Single Diaphragm Chrome Purifiers

- Chrome Collector

- Triple Diaphragm Cr Collector Unit In Working

- FRESH DIAPHRAGM SOLUTION

- CHROME ENRICHED SOLUTION

- Chrome Collector Unit

- Unique Chrome Collector

- Multi Diaphragm unit

- Single Diaphragm unit

- Chrome Collection In manual plant Drag Out

- TRIPLE DIAPHRAGM CHROME COLLECTOR UNIT

- Specific Diaphragms

- CHROME COLLECTOR UNIT WITH 12.5 LTR DIAPHRAGMS

- Etching Purifiers

- Etching Purifier

- ETCHING PURIFIER 12.5 LTR ON AUTO PLANT

- ETCHING PURIFIER 12.5 LTR IN AUTO PLANT

- ETCHING PURIFIER 3.3 LTR IN MANUAL PLANT

- Etching Purifier Working

- Multi Diaphragm unit

- ETCHING PURIFIER 3.3 LTR IN MANUAL PLANT (3)

- ETCHNG PURIFIER 3.3 LTR IN MANUAL PLANT (2)

- ETCHING PURIFIER IN OPERATION

- Single Diaphragm Etching Purifier (12.5 Ltrs)

- Etching Purifier Unit

- Single Diaphragm unit

- Specific Diaphragms

- ETCHING PURIFIER 12.5 LTR

- ETCHING PURIFIER 3.3LTR IN OPERATION

- ABS Etching Purifier

- Nickel Dummy Unit

- NICKEL DUMMY UNIT IN OPERATION

- ONLINE NICKEL DUMMY UNIT

- NICKEL DUMMY UNIT IN BARREL PLANT

- RAW DUMMY CARTRIDGE

- DUMMY CARTRIDGE AFTER CAPTURING IMPURITIES

- Online Working Of NI Dummy Unit

- WORKING Ni DUMMY UNIT

- ONLINE WORKING Ni-DUMMY UNIT

- Dummy Cell

- NICKEL DUMMY UNIT IN VAT

- Ni DUMMY UNIT SHOWING OPEN CANNISTER

- Nickel Dummy Unit Assembly

- Oil Retention Unit

- OIL RETENTION UNIT

- OIL RETENTION MEDIA

- Oil Retention Unit with Media

- Oil Retention Unit

- OIL RETENTION UNIT AT SOAK CLEANER

- OIL RETENTION UNIT AT AUTO LINE

- OIL RETENTION UNIT AT MANUAL PLANT

- DIFFERENT STAGES SAMPLES OF SOLUTION

- ORM UNIT OPEN CHAMBER SHOWING MEDIA

- Industrial Oil Retention Units

- DIFFERENT STAGES SAMPLES OF SOLUTION

- COLLECTED OIL FROM CLEANER SOLUTION

- Oil Retention Unit In Operation

- OIL RETENTION UNIT ON CLEANING LINE

- ORM UNIT AFTER CAPTURING OIL

- Aluminum E. D. System

- Equipments for Mining Industry

- Precious Metals Recovery Unit

- CARTRIDGE AFTER CAPTURING SILVER

- METAL RECOVERY UNIT WITH RECOVERED METAL

- RECOVERY CARTRIDGE AFTER CAPTURING GOLD

- THE RECOVERY UNIT WORKING PLAN

- METAL RECOVERY UNIT

- GOLD RECOVERY CARTRIDGE

- SILVER RECOVERY CARTRIDGE

- RECOVERY CARTRIDGE AFTER CAPTURING GOLD

- CARTRIDGE AFTER GOLD RECOVERY

- RECOVERY CELL OPENED IN PROCESS SHOWING GOLD

- RECOVERY CELL OPENED TO SHOW CAPTURED GOLD

- GOLD RECOVERY UNIT

- RAW RECOVERY CARTRIDGE

- RECOVERY UNIT

- Gallery

- Contact Us